How Do You Choose the Right Commercial Ceiling Fans? (The Ultimate U.S. Buyer’s & Engineering Guide)

A complete guide to choosing commercial ceiling fans in the United States performance, airflow, sizing, and efficiency for warehouses, gyms, restaurants, and offices.

Table of Contents

1) Introduction: Why Commercial Buildings Need Specialized Ceiling Fans

Commercial ceiling fans are essential for maintaining comfort, productivity, and energy efficiency in large indoor environments such as warehouses, gyms, restaurants, schools, and showrooms. Unlike small residential fans, these units are engineered for higher coverage, continuous operation, and integration with building-management systems (BMS). In 2025, U.S. businesses are turning to HVLS industrial fans and high-efficiency DC models to cut HVAC costs while improving air quality and occupant comfort.

Whether you’re running a retail space in Texas, a gym in Florida, or a warehouse in Ohio, the right ceiling fan can lower energy bills by 20–30 %, balance temperature gradients, and meet modern sustainability standards such as ASHRAE 55 and LEED v4.1. This guide explains how to select, size, and install the right fan system for your commercial environment.

2) How Commercial Ceiling Fans Work

Commercial fans operate on aerodynamic principles similar to airplane wings: the angled blades (airfoils) push large volumes of air downward, creating a broad, gentle circulation pattern. This process—called destratification—equalizes air temperature from floor to ceiling, minimizing HVAC workload.

- HVLS (High Volume, Low Speed) fans measure 7–24 ft in diameter and rotate slowly (≈ 40–70 RPM) to move hundreds of thousands of CFM with minimal noise.

- Medium-diameter commercial fans (52–84 in) suit offices, restaurants, and retail areas where aesthetics and low noise are priorities.

- High-speed directional fans are used for spot cooling in manufacturing zones or kitchens.

Figure 1 – Image Placeholder: “airflow-pattern-hvls-vs-standard.jpg” — cross-section showing broad HVLS airflow versus narrow residential pattern.

3) Core Performance Specifications

When evaluating fans for a commercial facility, focus on the following measurable criteria:

- Airflow (CFM): Cubic Feet per Minute — total air volume moved. Large fans can exceed 300 000 CFM.

- Efficiency (CFM/W): Energy output per watt; top HVLS models reach > 500 CFM/W.

- Motor Type:

- AC Induction – lower cost, less efficient.

- EC or DC Brushless – high torque, quiet, 60 % energy reduction.

- Noise Level (dB): Critical for restaurants (< 50 dB) and offices (< 45 dB).

- Blade Material: Aluminum or composite airfoils for strength and corrosion resistance.

- Mounting Height: Minimum 10 ft clearance to floor; optimum 15–30 ft for HVLS.

Figure 2 – Chart Placeholder: “cfm-per-watt-comparison.png” — bar chart comparing AC vs DC motor efficiency.

4) Common Commercial Applications

Commercial ceiling fans appear in almost every industry segment in the U.S., but airflow and noise requirements differ drastically. Below are representative use cases.

| Application Type | Typical Space Size | Recommended Fan Diameter | Air Velocity (ft/s) | Key Requirement |

|---|---|---|---|---|

| Warehouse / Distribution Center | 40 000 – 150 000 sq ft | 18 – 24 ft (HVLS) | 2 – 3 ft/s | Temperature equalization and HVAC support |

| Gym / Fitness Center | 10 000 – 25 000 sq ft | 14 – 20 ft | 2 ft/s | Quiet air movement and humidity control |

| Restaurant / Café | 2 000 – 6 000 sq ft | 52 – 72 in | 1.5 – 2 ft/s | Low noise, aesthetic design |

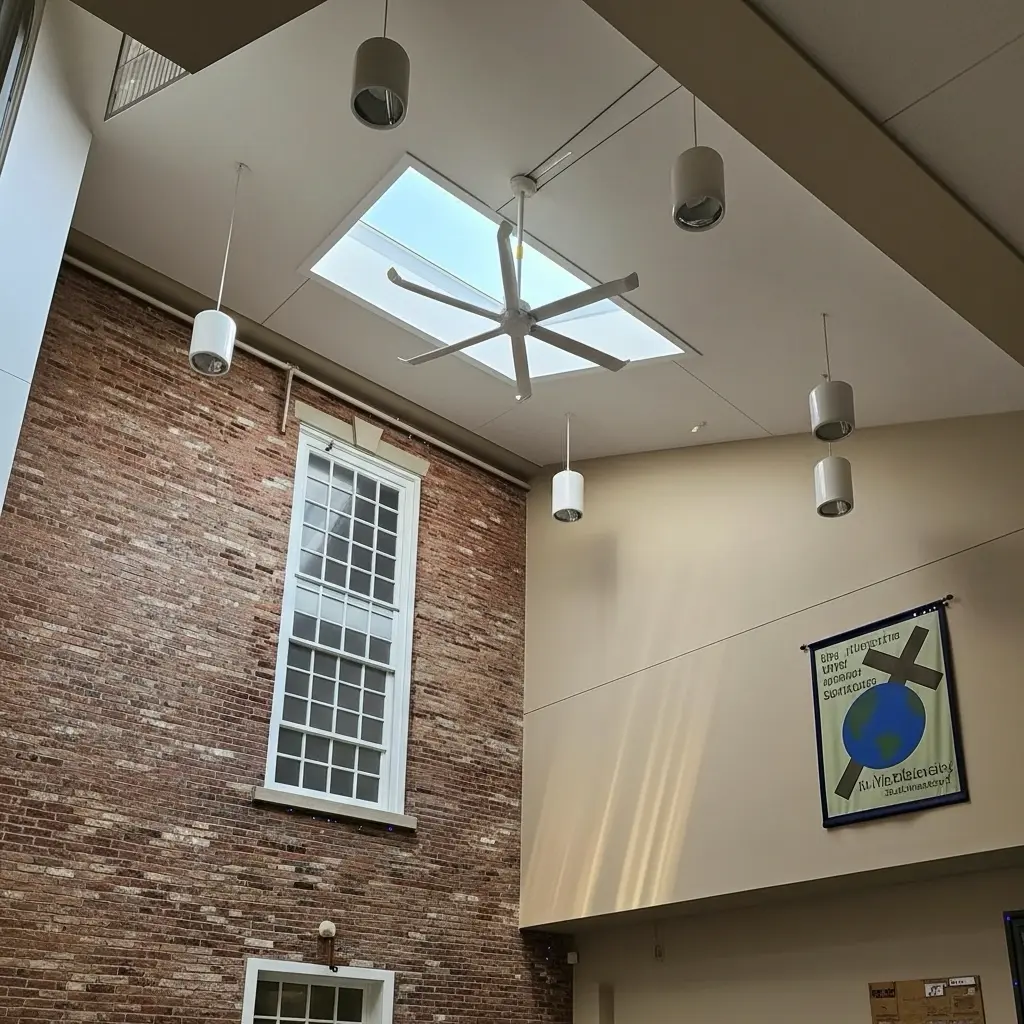

| Church / Auditorium | 8 000 – 30 000 sq ft | 16 – 20 ft | 2 ft/s | Silent operation and air mixing at height |

| Retail Store / Showroom | 5 000 – 20 000 sq ft | 84 in – 14 ft | 1.5 – 2 ft/s | Aesthetic and quiet airflow |

5) Sizing & Layout Guidelines

Proper sizing ensures even coverage and prevents dead zones. Use the formulas below as a baseline:

- Coverage Area (approx.) = π × (r2) × Ceiling Height Factor

- Each 24 ft HVLS fan covers ≈ 20 000–25 000 sq ft at 25 ft height.

- Maintain 60–100 ft spacing between fans for overlap and consistent floor velocity.

- Keep 2–3 ft clearance above blades and 10 ft minimum to floor per UL 507.

Figure 3 – Image Placeholder: “fan-spacing-diagram.png” — top-view layout showing coverage overlap for HVLS fans in a warehouse.

Example Sizing Table

| Ceiling Height (ft) | Fan Diameter (ft) | Coverage Area (sq ft) | Fan Spacing (ft) |

|---|---|---|---|

| 15 | 12 | ≈ 9 000 | 60 |

| 20 | 16 | ≈ 14 000 | 80 |

| 25 | 20 | ≈ 20 000 | 100 |

| 30 | 24 | ≈ 25 000 | 110 |

Use CFD (computational fluid dynamics) modeling or manufacturer design software for precise layout in complex buildings with obstructions like ducts or cranes.

6) HVLS vs Standard Commercial Fans Comparison

Both categories serve the commercial market, but each fits different building types. The table below summarizes key contrasts.

| Feature | HVLS Fan (High Volume Low Speed) | Standard Commercial Fan (High Speed Small Diameter) |

|---|---|---|

| Diameter Range | 7 – 24 ft | 3 – 7 ft |

| Speed (RPM) | 40 – 70 | 150 – 350 |

| Airflow (CFM) | 100 000 – 400 000 | 5 000 – 20 000 |

| Energy Use (W) | 400 – 1 000 | 60 – 120 |

| Efficiency (CFM/W) | ≈ 500 | ≈ 150 |

| Noise Level (dB) | 45 – 55 | 50 – 60 |

| Typical Use | Warehouses, gyms, barns | Offices, restaurants |

| Maintenance | Low (Direct-drive) | Medium (Belt or AC) |

| Cost Range (USD) | $4 000 – $12 000 | $150 – $800 |

Figure 4 – Chart Placeholder: “hvls-vs-standard-energy-chart.png” — side-by-side bars showing energy efficiency and coverage.

7) Engineering Note – Blade Design and Airflow Physics

Modern commercial fans use airfoil-shaped blades with variable pitch (8°–16°) to maintain consistent velocity along their length. This reduces turbulence and noise while maximizing CFM/W. Computational modeling shows that air speed at the floor increases linearly with blade pitch angle up to ≈ 14°, after which drag dominates and efficiency drops.

Figure 5 – Chart Placeholder: “blade-pitch-vs-cfm-graph.png” — line graph

8) Brand & Performance Comparison (2025 U.S.)

When selecting a commercial ceiling fan, consider airflow output, energy efficiency, warranty, and integration features. Below is a snapshot of leading manufacturers and their 2025 flagship models.

| Brand / Series | Diameter (ft) | Airflow (CFM) | Power (W) | CFM / W | Noise (dB) | Motor Type | Warranty |

|---|---|---|---|---|---|---|---|

| Big Ass Fans – Powerfoil D | 24 | ≈ 380 000 | 850 | 447 | 52 | Direct-drive DC | 15 yr mechanical |

| Hunter Industrial – Titan II | 24 | ≈ 360 000 | 800 | 450 | 53 | EC motor | 10 yr limited |

| MacroAir – AirVolution D3 | 20 | ≈ 310 000 | 680 | 456 | 50 | Direct-drive PMSM | 12 yr |

| Marut Air – Elite Series | 18 | ≈ 210 000 | 520 | 404 | 54 | EC | 10 yr |

| Hampton Bay – Commercial HVLS | 16 | ≈ 160 000 | 400 | 400 | 51 | DC | 5 yr |

Figure 6 – Chart Placeholder: “cfm-per-w-brand-comparison.png” — bar chart showing efficiency across brands.

9) Cost & ROI Analysis

Upfront cost varies by fan diameter and motor type, but lifecycle savings are consistent across U.S. climates. The table below estimates energy savings at $0.14 /kWh and 8 h daily operation.

| Facility Type | Fan Size (ft) | Installed Cost (USD) | Annual Energy Use (kWh) | Annual HVAC Savings | Simple Payback |

|---|---|---|---|---|---|

| Texas Warehouse (60 000 sq ft) | 24 | $10 000 | 450 | $2 200 / yr | ≈ 4.5 yrs |

| Florida Gym (20 000 sq ft) | 18 | $6 000 | 300 | $1 200 / yr | ≈ 5 yrs |

| California Restaurant (5 000 sq ft) | 8 | $900 | 150 | $180 / yr | ≈ 5 yrs |

Utility rebate programs in Texas, California, and New York often cover 10–20 % of purchase cost for verified HVLS installations. Combining fans with BMS scheduling extends payback improvements by roughly 1 year.

10) Controls & Smart Integration

Advanced controls elevate fan performance beyond manual wall switches. Typical options include:

- BMS Integration: BACnet / Modbus protocols synchronize fan speed with HVAC demand.

- Temperature Sensors: Adjust RPM automatically to maintain ± 2 °F floor-to-ceiling spread.

- Occupancy Sensors: Activate airflow only during occupied hours, saving up to 25 % energy.

- Smart App Control: Wi-Fi modules allow scheduling and grouping via cloud dashboard.

Figure 7 – Image Placeholder: “bms-integration-diagram.png” — schematic showing HVAC and fan communication via BACnet.

11) Maintenance Schedule & Safety Standards

Commercial fans require minimal upkeep but must adhere to UL and OSHA protocols for safe operation.

| Task | Frequency | Purpose |

|---|---|---|

| Clean blades & motor housing | Quarterly | Prevents dust imbalance and maintains airflow. |

| Check fastener torque | Every 6 months | Ensures mount integrity and vibration control. |

| Inspect electrical connections | Annually | Avoids arcing and thermal degradation. |

| Verify safety cables & brackets | Annually | Complies with OSHA 29 CFR 1910 overhead equipment rules. |

12) Regional U.S. Case Studies

- Texas Distribution Hub – Dallas: Six 24 ft HVLS fans lowered average warehouse temperature by 8 °F and saved $9 000 / year in A/C energy.

- Florida Fitness Center – Tampa: 18 ft fans cut humidity by 15 %, preventing condensation on equipment.

- Ohio Manufacturing Plant – Toledo: Two 22 ft Hunter Titan fans improved worker comfort zone scores by 30 % on ASHRAE 55 scale.

- California Restaurant Chain – San Diego: Smart DC fans integrated with thermostats reduced HVAC runtime by 20 % and qualify for PG&E rebate.

Figure 8 – Image Placeholder: “us-case-study-map.png” — map highlighting TX, FL, OH, CA fan projects.

13) Environmental Impact & LEED Certification

Installing commercial HVLS fans supports multiple LEED v4.1 credits:

- EA Credit 1 – Optimize Energy Performance: Reduced HVAC demand equals documented energy savings for points.

- IEQ Credit 7 – Thermal Comfort: Improved air mixing meets ASHRAE 55 comfort parameters.

- MR Credit 4 – Low-Emitting Materials: Powder-coat and recycled aluminum blades qualify for green materials points.

Typical emission reduction per fan ≈ 2–5 tons CO₂e annually by offsetting HVAC electricity use.

14) Conclusion

Commercial ceiling fans are no longer luxury fixtures but critical infrastructure for energy-efficient buildings. Whether you manage a gym in Florida or a warehouse in Texas, HVLS and high-efficiency fans enhance comfort, reduce costs, and support sustainability goals. Select direct-drive DC models for lowest maintenance, verify UL 507 / NEC 314.27 compliance, and leverage rebates to accelerate ROI.

Need help sizing a commercial ceiling fan?

Get a free consultation from U.S. HVLS specialists and receive custom layout designs for your facility. Explore HVLS Industrial Fans Guide →